Quality Matters

Quality of work is of utmost importance across all operations in our organization. Everyday tasks are driven by well implemented standards and procedures. Our SAP system ties in all aspects of the company to ensure standards and procedures are followed.

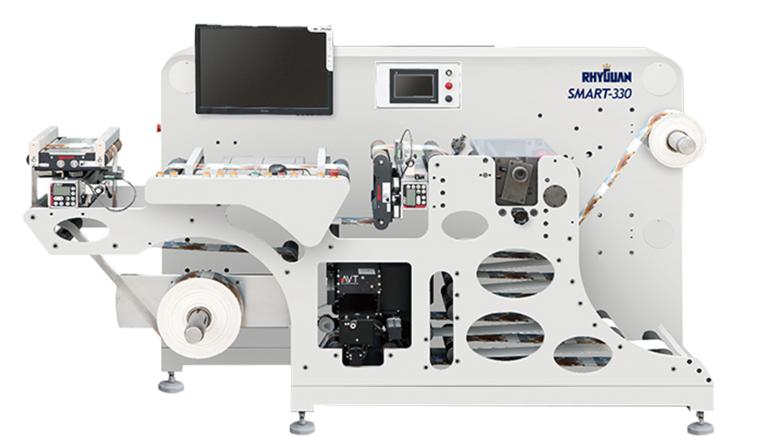

From quality of primary machines to quality checking equipment and in training, we take the utmost care to promote a quality mind set.

In Process Quality Control

We maintain a strong in-process quality control system and a stringent line clearance system to ensure every job goes passes a wide range of checkpoints before and during production. A well trained team of dedicated IPQC personnel ensure compliance as per sampling plan.

As an additional measure of risk reduction for our customers, we have invested heavily in fully automated defect detection systems. By maintaining a 1:1 ratio of inspection machines to printing machines, we ensure that sufficient inspection resources are allocated. This allows us to machine check every single label that is produced.